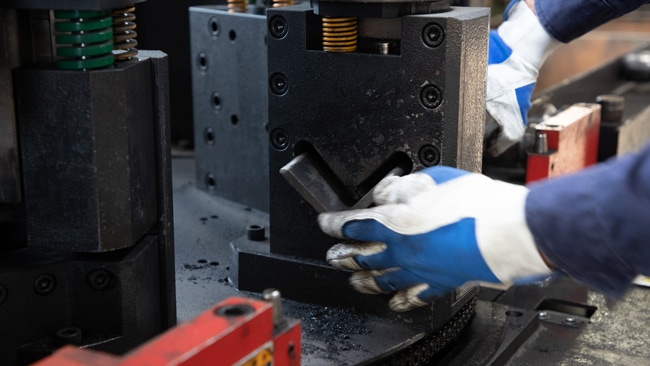

01Full In-House Production, from the Parts Up

We strive to the greatest possible extent to manufacture our own parts. Focusing more on in-house production than efficiency enables us to create detailed, high-quality custom specifications for original electric furnaces and other products. We offer maintenance services as well.

Promoting in-house production requires both human resources and equipment. Outsourcing parts may be the natural option when efficiency alone is considered. However, since this also involves a key technical issue, we prefer to manufacture these parts ourselves rather than outsourcing it to an outside company. As this increases customer confidence and expands our range of technologies, we therefore believe it enhances our company’s strengths.

02Advanced Craftsmanship

Since our founding in 1954, we have gained a wealth of experience in meeting the diverse needs of all industries, from automobiles to semiconductors, passing down this experience in the form of our peerless craftsmanship. We take particular pride in the fact that our advanced heat treatment technology for electric furnaces is always on the cutting edge.

There are many plants that cannot fabricate metals even if they make a furnace.

This is because metal fabrication requires master welding skills. In addition to that, our craftsmen exhibit their superior skills and ensure quality in every stage of the manufacturing process, including the advanced heat treatment required for electric furnaces, the advanced processing required for molybdenum heaters and other products, and precision fitting of brick for the various furnace shapes.

Not assigning each craftsman a specific role allows us to create a work environment where a single person can perform multiple tasks. Individuals have their own interests that they enjoy while pursuing what they want to do, with their technical skills improving as well. They share this with their co-workers, forming a vigorous group of craftsmen. In addition, the craftsmen who make these products are themselves in charge of maintenance and provide support to ensure use of the product over the long term.

03Breadth and Depth in Proposals

The technologies and experience we have developed by manufacturing in-house enable us to offer a wide range of proposals. It’s not uncommon for consultations to start with the question, “Can you do something like this?” We then suggest the procedures and methods that make it possible.

Our ability to integrate manufacturing at our own plants means that when we get an idea and want to try it out, the company has the sites, equipment, and technologies to carry out prototyping and testing. And our commitment to manufacturing in-house results in proposals that are available only from us, as we’ve become able to make anything. By combining designs and sites, matching craftsmen with other craftsmen, along with their respective skills, we respond to customer requests with proposals that exceed their expectations.

04Extensive Overseas Experience

We have a proven track record of delivering products to businesses abroad, from Japanese overseas affiliates to locally-based companies. We also offer on-site installation and maintenance. We provide industrial electric furnaces that support the foundations of manufacturing overseas, thereby helping support manufacturing worldwide.

[Customer Countries]

USA, Mexico, Brazil, Thailand, India, Indonesia, South Korea, China, Malaysia